Mineral plaster is a natural, environmentally friendly material, representing a mixture of dry construction, which is used for both internal and external works. All the details you need to know about mineral plaster: description, applying technique, photos and real examples of the resulting surface see below.

The Composition of Mineral Plaster and its Application

Mineral plaster is made on the basis of lime hydrate, marble granules, white, and light high-quality Portland cement mineral fillers. This plaster is very economical and suitable for lightweight building fillers. Although the composition of plaster has lime, which does not tolerate water, the material itself can be easily cleaned and washed because it is based on substances that do not let lime “melt”.

The material is designed for interior decoration and for facade work. By the way, during exterior works facade stucco is often used in the insulation system. Mineral decorative plaster is not fastidious in the work. Accordingly, it can be applied to any mineral substrates, including gypsum and plaster, asbestos, plywood, fiberboard, chipboard, concrete, and drywall. But nevertheless, the mixture is best suited for the walls, which are prone to abrasion or have raised surfaces (entrances, staircases, corridors, etc.) as well as the cap of buildings.

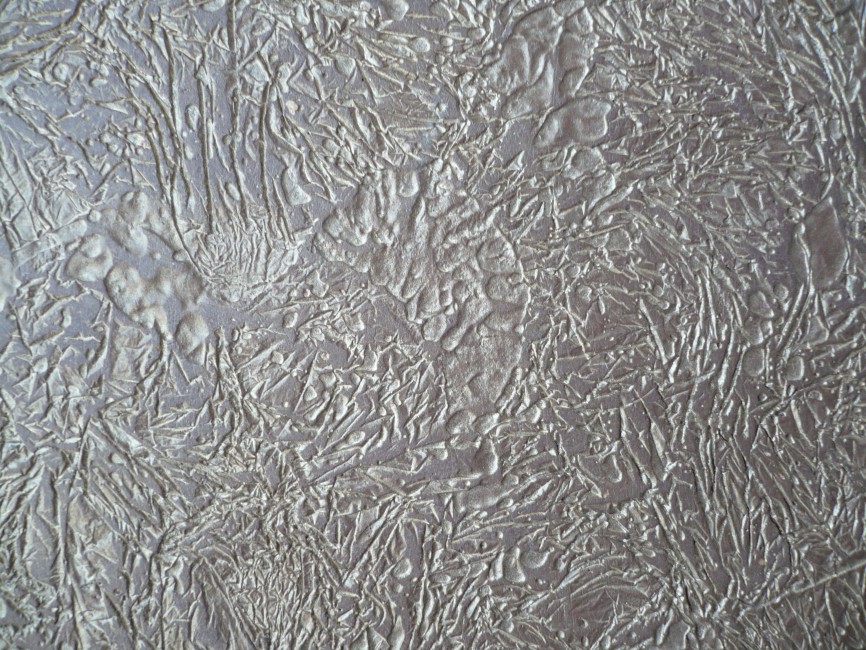

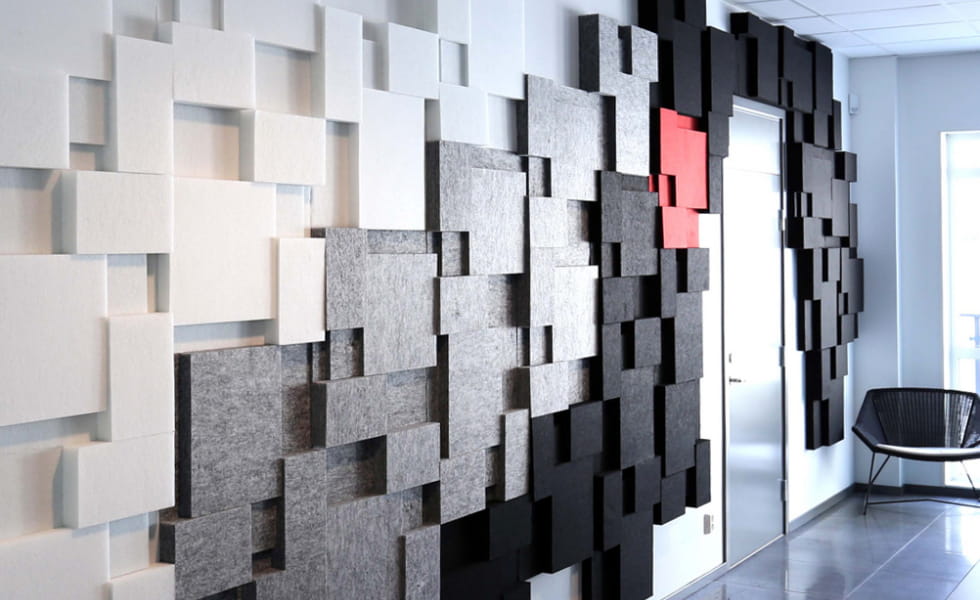

Photos of Real Works with Mineral Plaster

Mineral decorative plaster: advantages

- environmentally friendly material;

- high resistance to mechanical damage and atmospheric precipitation;

- resistance to temperature changes and frost resistance;

- allows the walls to “breathe”;

- fireproof;

- maintain easiness (you can use any detergents for cleaning).

The Technique of Mineral Plaster Applying

- The surface should be thoroughly cleaned, leveled, and dried.

- Next step: you need to clean the surface of the old finishing materials. The removal of each material has its difficulties. For more details of the whole process, read here. After that, you need to putty the defective areas on the surface and prime them.

- Wait until the wall is dry. Then you can start applying the material.

- According to the instructions on the package, it is necessary to dissolve the dry mortar with water adhering to these recommendations.

- Next, you need to process the entire wall without interruption, from corner to corner. At the corners and joints is best to use masking tape which allows achieving a smooth surface. You need to read the instructions beforehand on how many layers are recommended to apply. The amount may vary depending on the manufacturer. The material should not be used at a temperature below 5C. The material dries within 3 days.